What is a CNC Machine?

CNC machining is a manufacturing process in which pre-programmed software commands the movement of factory tools and machinery. The process can be used to control a range of intricate machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be achieved in a single set of commands. CNC machining is a digital manufacturing technology: it produces high-accuracy parts with excellent physical properties directly from a CAD file.

The basic CNC process is done in 3 steps. The machinist first creates the designs of the CAD model of the part/product. Then the CAD file is turned into a CNC program (G-code) and sets up the machine. Lastly, the CNC system executes all machining operations with little supervision, removing material and creating the part/product.

There are various types of CNC machines that are used in different industries. Let us shed some light on the CNC machine and its background.

The meaning of CNC

The full form of CNC is Computer Numerical Control. You can think of it as an extension of NC that refers to Numerical control. The basic idea behind CNC is using a computer to control machine tools. The CNC machine can be thought of like a robot.

Various things can be controlled via the NC programs in the machines. These include the likes of the speed of moving cutter, turning the spindle, the direction of the cutter in axis, turning the coolant on and off, among other things.

A bit about CNC machines

Initially, machinists used to operate machine tools. However, CNC machines are machine tools controlled via computers.

A computer can control servos operating the machine with CNC. These machining robots enhance productivity significantly as they make sure that operators are needed for the machinery to operate. Therefore, the machine can continue operating for a long time automatically without any continuous attention required.

Before this CNC machine system was introduced, hydraulic tracer systems offered simple automation in which the tools followed a temperature via hydraulics.

However, things changed drastically with CNC as the amount of automation provided during manufacturing increased significantly. While there is no denying that manual machining is quite common even currently for prototyping and repairs, CNC machining has undoubtedly taken over as the primary method of machining materials. Those who run CNC machinery are called CNC operators, while CNC programmers are the ones who write the programs for automating the production.

History of CNC

It was in the 1950s that the first commercial NC machine was built. This machine was operated via punched tape. The concept took some time to catch on, as it was quite different from what people were used to. However, it was evident that it was a cost-friendly idea.

To increase the prevalence of these machines, the US army purchased 120 of them, loaning them to different manufacturers. This made sure that the manufacturers got some idea about its operation. As the end of the 50s neared, the concept was NC was no longer new, but a bit of work was still required.

During that time, G-code did not exist. Thus, every manufacturer tried to use his own language to define numerical control. This made things a bit complicated and confusing. It was in 1958 that G-code originated in MIT, which gave a new lease of life to NC machine. CNC machines became powerful and readily accessible with the availability of minicomputers.

Employment costs were on the rise during 1970 due to the slowing down of the economy. Thus, CNC started taking over from the older technologies. US companies get credit for being the starters of the CNC revolution. However, it was the Germans who played a role in reducing the prices of these machines and therefore making them more prevalent. The reins were then taken over by Japanese.

Application of CNC machines

There is no denying that the old numerical control days are now a thing of the past. CNC machining is what rules the industrial world these days. You might be wondering about the application of CNC machines and what it can be used for. Let us shed some light on this.

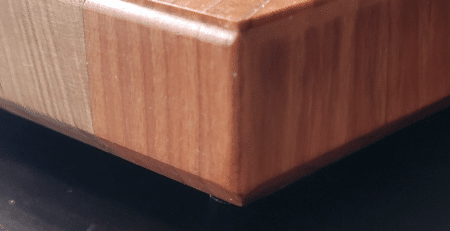

Routing with wood

CNC machines are used heavily in the woodworking industries to perform different operations like routing (similar to milling) and drilling. CNC carving wood is a useful process, not just because of the size capabilities, but also for the aesthetic and material properties of wood. CNCs do have some major advantages in woodworking which include creating intricate designs that would be either far too difficult or time-consuming by hand.

Removal of metal

CNC machine is of immense value in the metal removal industries. These include the likes of automotive industries, aerospace industries, and jewelry making, among others. Using this technology, excess metal is removed from the raw materials so that the desired end product can be acquired. The CNC machine is also useful in creating shaped products such as rounded, threaded, square, and rectangular products. Three-dimensional products can also be created using these machines.

Fabricating metals

A lot of industries need thin metal plates to create their end products. CNC machines can make tasks of fabricating metals quite feasible. These include drilling, flame and plasma cutting, precision holes, shearing, and welding, among others. Various industries benefit a great deal from this application of the CNC machine. Some examples include:

Electronics: It is necessary that the tiny parts of computers and motherboards are made with immense precision.

Firearms: The CNC machine is also used for creating barrels and ammunition clips. Pins, triggers and parts of guns are also manufactured via CNC machining

Final words

Technological advancements have come a long way. We have made so much progress in the field that many would not have deemed possible a few years ago. CNC machining is an excellent example of technology that has increased productivity. CNC machines also play a significant role in improving quality and ensuring that parts of machines are made with precision.

The professionals at The Original WorkShop can design your next perfect and unique gift using our CNC technology. The ideas are endless! Contact us today for more information.