Best Types of Dovetail Joints for Woodworking

Best Types of Dovetail Joints for Woodworking

Do you struggle with making strong, attractive dovetail joints in your woodworking projects? This article covers the best types of dovetail joints for woodworking and explains how each type can improve project durability and appearance. The content presents key joint techniques and their benefits to help resolve common issues in joint construction. Readers will gain clear guidance to boost both their skills and project quality. dovetail joints woodworking.

Key Takeaways

- through dovetail joints provide strength and visual appeal in cabinet and drawer construction

- half-blind dovetail joints offer hidden tails for clean furniture joinery

- full-blind dovetail joints create sturdy connections with hidden profiles and precise fittings

- sliding dovetail joints achieve robust interlocking fits in cabinetry using adhesives and measured cuts

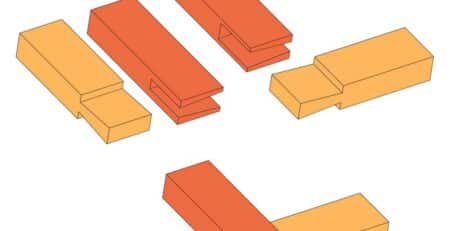

Types of Dovetail Joints

The article examines different dovetail joints, covering Through Dovetail Joint, Half-blind Dovetail Joint, Full-blind Dovetail Joint, and Sliding Dovetail Joint. It explains their use in woodworking projects and applications from ancient egypt designs to modern tool applications, marquetry work, dowel integrations, and box assemblies.

Through Dovetail Joint

The through dovetail joint offers strong joinery that is ideal for visible woodworking projects such as boxes and cabinets. It relies on precise jig placement to achieve accurate tail alignment and minimizes issues often seen with

| Key Feature | Application | |

| Through Dovetail | Exposed tails for visual appeal and strength | Cabinet making, drawer construction |

| Half-blind Dovetail | Hidden tails to suit polished surfaces | Furniture joinery |

| Sliding Dovetail | Versatile interlocking design | Woodturning projects, shelving units |

This joint is favored by experienced woodworkers who value both strength and aesthetics in joinery. Practical examples show that using a dedicated jig can further improve accuracy by aligning each tail perfectly, making it a reliable method even when compared to more traditional methods like a miter joint, with benefits extending into woodturning applications where precision is

Half-blind Dovetail Joint

The half-blind dovetail joint demonstrates refined woodworking skills by concealing the tail while retaining an effective mechanical hold. This technique is often combined with a rabbet to improve strength, and professionals emphasize its use in projects that include particle board applications, as discussed in various woodworking newsletter updates.

Experts favor the half-blind dovetail joint for its clean finish and precise alignment when constructing drawers and cabinets. It is a common choice in woodworking classrooms and workshops, where instructors guide students on the use of a coping saw to fine-tune joint details during

Full-blind Dovetail Joint

The full-blind dovetail joint offers a clean and sturdy connection for high-end woodworking projects. Professionals often use a mallet and precise machine adjustments to secure the joint, ensuring that each piece of lumber aligns perfectly without visible tails, even when screws are used for extra reinforcement. For more information, you can visit

Skilled craftsmen appreciate the reliability of dovetail joints in creating refined pieces that meet both structural and aesthetic requirements. Experts recommend using a carefully set machine and a proper mallet strike to achieve tight interlocking pieces, demonstrating the joint’s strength when working with quality lumber and a few well-placed screws.

Sliding Dovetail Joint

The sliding dovetail joint offers a precise method for joining wood that excels in cabinetry applications, ensuring a robust connection when installed with a proper adhesive and verified with a chisel. Using a bandsaw to precisely cut the dovetail profile enables woodworkers to achieve a tight, interlocking fit that withstands everyday use. The technique also involves a dado setup to ensure accurate alignment, minimizing.

This joinery method is well-suited for projects requiring a blend of strength and elegance in woodworking. Craftsmanship will benefit from the use of a chisel for fine adjustments and a bandsaw for consistent cuts, resulting in reliable cabinetry construction. The integration of an adhesive and careful dado measurements further enhances the joint’s durability and overall performance in practical scenarios.

Conclusion

Woodworkers appreciate the clarity and precision provided by dovetails when combining hand tool accuracy with modern power tool use. Precision in dovetail construction supports seamless assembly and strong joints that satisfy design requirements.

The use of a table saw and hand tool techniques refines each dovetail cut and helps maintain steady progress during wood construction. Clear measurements and a fastener approach further boost project durability.

Skilled craftsmen use dovetails to join pieces with accuracy, ensuring that every cut and interlock fits correctly. Cross-checking with a hand tool enhances reliability in both manual and machine-assisted work.

Reliable fastener installation and dovetail integration using a table saw and hand tool techniques ensure every project meets high construction standards. This method supports smooth, efficient work and a lasting final product.

Frequently Asked Questions

What Are Common Types of Dovetail Joints in Woodworking?

Woodworking applications often use through dovetails, half-blind dovetails, and sliding dovetails for joints, each offering sturdy connections, precision machining, and attractive design attributes. fine woodworking magazine

How do dovetail joints impact structural strength?

Dovetail joints provide notable stability and durability due to their interlocking design. The precise woodworking technique distributes stress evenly, boosting overall structural strength in cabinetry and furniture applications. Dovetail joints woodworking can significantly improve the quality of your projects.

Which joint works best for drawer construction?

Dovetail joints provide excellent support and durability for drawer construction. They ensure a secure fit, resist wear, and deliver stable performance in woodworking projects, including

Are angled joints preferable for decorative furniture?

Angled joints add a distinctive visual interest and deliver robust connections in decorative furniture, especially when paired with precise CNC and woodworking techniques for optimal performance.

Can CNC machines produce precise dovetail joints?

Yes, CNC machines produce precise dovetail joints, achieving consistent results with tight fits and accuracy. Their automated control minimizes manual errors, offering a reliable option for high-quality woodworking projects.

Conclusion

Best dovetail joints serve as a foundation for robust and visually appealing woodworking projects. Each style offers unique advantages based on visibility, mechanical strength, and assembly technique. Woodworkers achieve remarkable accuracy and reliability by employing specialized tools and meticulous measurements across these joint types. Skilled craft ensures long-lasting, refined assemblies that meet both aesthetic and structural expectations.

Contact us for your Custom project today!