Unlocking the Potential of CNC Designs in Woodworking: A Creative Journey

Are you searching for new ways to unleash your creativity in the world of woodworking? Look no further than CNC designs. With the advancement of technology, CNC (Computer Numerical Control) machines have revolutionized the woodworking industry, offering endless possibilities for intricate and precise designs. In this article, we embark on a creative journey to explore the potential of CNC designs in woodworking.

Using state-of-the-art software and machinery, CNC designs open up a whole new world of possibilities for woodworkers. From intricate furniture designs to personalized ornaments and decorative pieces, the capabilities of CNC machines are truly awe-inspiring. The precision and accuracy of these machines allow woodworkers to bring their innovative ideas to life with ease.

In addition to their precision, CNC designs can also speed up the manufacturing process, ultimately saving time and resources. By automating certain tasks, woodworkers can focus on the artistic aspects of their craft, pushing boundaries and creating unique pieces that stand out.

Join us as we delve into the world of CNC designs in woodworking, uncovering the transformative power and boundless creative potential they hold. Get ready to be inspired and unlock your imagination as we explore the possibilities together.

Advantages of using CNC technology in woodworking

The emergence of CNC technology has revolutionized the woodworking industry, offering a multitude of advantages that have transformed the way woodworkers approach their craft. One of the primary benefits of using CNC technology in woodworking is the unparalleled precision and accuracy it provides. CNC machines are equipped with advanced software and state-of-the-art cutting tools that allow for intricate and complex designs to be executed with remarkable consistency and repeatability.

This level of precision is particularly valuable in the creation of custom furniture, cabinetry, and other woodworking projects, where even the slightest variation can be detrimental to the overall aesthetic and functionality of the piece. With CNC technology, woodworkers can achieve a level of detail and consistency that would be nearly impossible to replicate manually, ensuring that each and every component of a project is perfectly aligned and proportioned.

Another significant advantage of CNC technology in woodworking is the increased efficiency and productivity it offers. CNC machines are capable of performing complex operations with speed and efficiency, reducing the time and labor required to complete a project. This, in turn, allows woodworkers to take on more commissions, expand their product offerings, and ultimately, increase their profitability. Additionally, the automation provided by CNC technology can help to minimize the risk of human error, further contributing to the overall quality and consistency of the final product.

Types of CNC machines used in woodworking

In the realm of woodworking, there are several types of CNC machines that have become essential tools for modern craftsmen. One of the most commonly used CNC machines in woodworking is the CNC router, which utilizes a rotating cutting tool to precisely carve and shape wood, creating intricate designs and patterns. These machines are highly versatile, capable of handling a wide range of materials, from solid wood to plywood and even some composites.

Another popular CNC machine in the woodworking industry is the CNC lathe, which is specifically designed for turning and shaping cylindrical or symmetrical objects. These machines are particularly useful for the creation of furniture components, such as table legs, chair spindles, and other turned elements. The CNC lathe’s ability to produce consistent and accurate shapes is invaluable in the production of high-quality woodworking projects.

In addition to routers and lathes, some woodworkers also employ CNC milling machines, which are adept at creating complex three-dimensional shapes and contours. These machines are often used in the production of custom cabinetry, architectural elements, and sculptural woodwork, where the ability to precisely cut and shape wood is essential. CNC milling machines can be equipped with a variety of cutting tools, allowing woodworkers to tackle a diverse range of projects with a single machine.

Creating intricate designs with CNC technology

The true power of CNC technology in woodworking lies in its ability to create intricate and complex designs that would be incredibly challenging, if not impossible, to achieve through traditional hand-carving or manual techniques. By leveraging specialized CAD (Computer-Aided Design) software, woodworkers can design and visualize their projects in a digital environment, allowing them to experiment with various shapes, patterns, and textures before committing to the physical execution.

Once the design is finalized, the CNC machine can then translate these digital plans into physical reality, precisely cutting and shaping the wood to the desired specifications. This process enables woodworkers to bring their most ambitious and intricate ideas to life, from delicate filigree patterns to intricate three-dimensional sculptures. The level of detail and complexity that can be achieved with CNC technology is truly awe-inspiring, pushing the boundaries of what is possible in the world of woodworking.

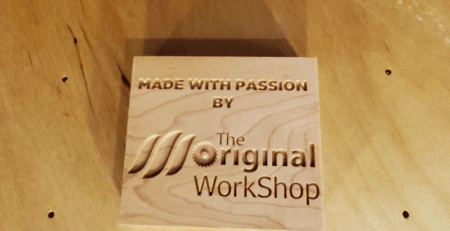

Furthermore, the use of CNC technology allows for the seamless integration of various design elements, such as inlays, engravings, and even the incorporation of digital imagery or text. This opens up a world of creative possibilities, allowing woodworkers to personalize their projects, create unique and customized pieces, and truly express their artistic vision. The precision and repeatability of CNC machines ensure that these intricate designs are executed with exceptional consistency, resulting in a level of craftsmanship that would be difficult to replicate through manual methods alone.

Customizing woodworking projects with CNC designs

One of the most exciting aspects of incorporating CNC technology into woodworking is the ability to customize and personalize projects to suit the individual needs and preferences of clients or end-users. With the help of CNC machines, woodworkers can create truly bespoke pieces that cater to the unique requirements and aesthetic sensibilities of their customers.

Whether it’s a custom-designed piece of furniture, a personalized home decor item, or a one-of-a-kind gift, CNC technology provides the tools and flexibility to bring these custom creations to life. By leveraging the design capabilities of CAD software, woodworkers can collaborate closely with their clients to develop tailored solutions that reflect their individual style, preferences, and functional needs.

The versatility of CNC machines also allows for the incorporation of personal elements, such as monograms, inscriptions, or even photographic imagery, into the final design. This level of customization not only enhances the emotional connection between the customer and the product but also elevates the overall value and uniqueness of the piece. Woodworkers who embrace the power of CNC technology can differentiate themselves in the market, offering their clients truly exclusive and personalized woodworking creations that stand out from the mass-produced alternatives.

CNC designs for furniture making

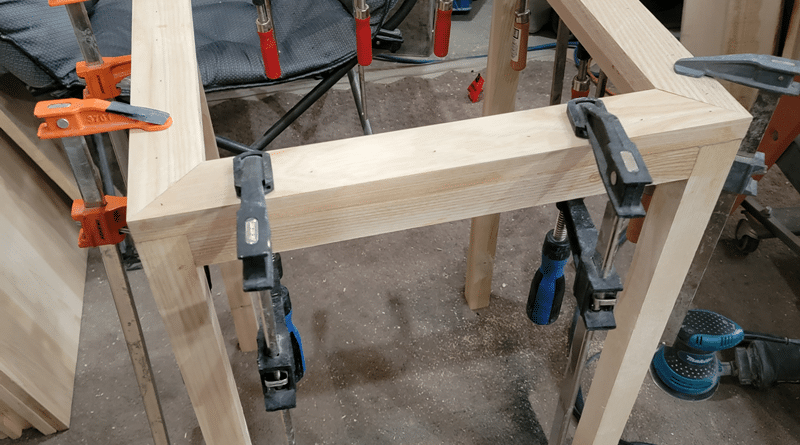

The application of CNC technology in furniture making has opened up a world of creative possibilities, allowing woodworkers to push the boundaries of traditional furniture design. With the precision and flexibility offered by CNC machines, designers and craftsmen can now create intricate, sculptural, and highly customized furniture pieces that would have been nearly impossible to achieve through manual methods.

From the intricate carved details adorning the legs and aprons of a dining table to the seamless integration of digital imagery or text into the design of a dresser or armoire, CNC technology has transformed the way we approach furniture making. Woodworkers can now experiment with complex, organic shapes, fluid curves, and intricate patterns, confident in the knowledge that their designs can be executed with unparalleled accuracy and consistency.

Furthermore, the use of CNC machines in furniture making can also enhance the functionality and ergonomics of the final product. By incorporating precise measurements and optimized designs, woodworkers can create furniture pieces that not only look stunning but also provide superior comfort and usability for the end-user. This level of attention to detail and customization is particularly valuable in the production of specialized furniture, such as adjustable workstations, ergonomic seating, and custom-fitted cabinetry.

Incorporating CNC designs in cabinetry

The impact of CNC technology on the cabinetry industry cannot be overstated. The precision and versatility of CNC machines have revolutionized the way woodworkers approach the design and fabrication of custom cabinets, allowing them to create truly exceptional and innovative pieces that cater to the specific needs and preferences of their clients.

From the intricate door and drawer fronts to the seamless integration of hardware and accessories, CNC technology has empowered cabinetmakers to push the boundaries of traditional cabinet design. Woodworkers can now experiment with complex geometric patterns, intricate carvings, and even the incorporation of digital imagery or text, elevating the visual appeal and uniqueness of their cabinetry creations.

Moreover, the use of CNC machines in cabinetry has also enhanced the efficiency and accuracy of the production process. By automating certain tasks, such as cutting, drilling, and routing, cabinetmakers can reduce the time and labor required to complete a project, ultimately improving their overall productivity and profitability. This, in turn, allows them to take on more commissions, expand their product offerings, and better serve the needs of their clients.

CNC designs for artistic woodworking

The realm of artistic woodworking has been profoundly transformed by the integration of CNC technology. This powerful tool has empowered woodworkers to explore new frontiers of creative expression, unleashing a world of possibilities for the creation of intricate, sculptural, and visually stunning works of art.

With the precision and versatility of CNC machines, woodworkers can now bring their most ambitious and imaginative ideas to life, crafting three-dimensional sculptures, intricate wall panels, and even large-scale architectural installations. The ability to precisely cut, shape, and carve wood has opened up new avenues for artistic experimentation, allowing woodworkers to push the boundaries of traditional woodworking techniques.

Furthermore, the integration of CNC technology has also enabled the seamless incorporation of digital elements into the artistic woodworking process. Woodworkers can now seamlessly integrate digital imagery, patterns, and even text into their designs, creating truly unique and captivating works of art that blend the digital and the physical realms. This fusion of technology and traditional craftsmanship has resulted in the emergence of a new generation of artistic woodworkers, who are redefining the very nature of what is possible in this timeless medium.

Exploring the creative possibilities of CNC technology in woodworking

As the woodworking industry continues to evolve, the creative potential of CNC technology has become increasingly evident. Woodworkers who embrace this transformative tool are discovering a world of boundless possibilities, where the limits of their imagination are the only constraints.

By leveraging the precision, efficiency, and versatility of CNC machines, woodworkers can now tackle projects and designs that were once considered impossible or impractical. From the creation of intricate, sculptural furniture pieces to the production of highly personalized home decor items, the applications of CNC technology in woodworking are truly endless.

As woodworkers continue to push the boundaries of what is possible, we can expect to see a proliferation of innovative and groundbreaking designs that challenge the very definition of what it means to work with wood. The integration of CNC technology has not only streamlined the production process but has also opened up a world of creative possibilities, empowering woodworkers to express their artistic vision in ways that were once unimaginable.

Conclusion: Embracing CNC designs for innovation in woodworking

In the ever-evolving world of woodworking, the integration of CNC technology has proven to be a transformative force, unlocking a realm of creative possibilities that were once beyond the reach of even the most skilled craftsmen. By embracing the precision, efficiency, and versatility of CNC machines, woodworkers have the power to redefine the very boundaries of their craft, pushing the limits of what is possible and creating truly exceptional and innovative works of art.

As we have explored in this article, the advantages of using CNC technology in woodworking are numerous and far-reaching. From the unparalleled precision and accuracy of CNC designs to the ability to customize and personalize projects, this transformative tool has revolutionized the way woodworkers approach their craft. Whether it’s the creation of intricate furniture pieces, the seamless integration of CNC designs in cabinetry, or the exploration of artistic woodworking, the potential of CNC technology is truly boundless.

As we move forward, it is clear that the future of woodworking lies in the embrace of CNC technology. By harnessing the power of this innovative tool, woodworkers can unlock new realms of creativity, push the boundaries of traditional techniques, and ultimately, redefine the very nature of what is possible in the world of woodworking. So, let us embark on this exciting journey, where the only limit is the depth of our imagination and the skill of our hands.