5 Types of CNC Router Bits

The secret of success of CNC machines lies in the CNC router bits. The final design depends on these bits. Not only do the CNC router bits influence the outcome of the design, but they also have a role to play in the cost of manufacturing.

The CNC router bit is used for removing material in a particular manner. Initially, handheld tools were used for this purpose, which was guided by ball-bearing pilots and templates. However, things have changed with time and technological advancements, and now computers control the routers. It is the bits that make sure that CNC routers make cuts with intricacy and precision.

Types of CNC router bits

A lot of diverse options are available in the design cuts and materials of CNC router bits. Let us take a look at some of the standard options you will come across.

V-groove bits

The design cut of this bit is self-explanatory by its name; that is, it cuts in the V shape. The included angles might vary, and their best use is determined by these angles. For instance, a router bit with 90? offers a wider cut and thus is suitable for cutting shallow letters. Similarly, 60? bit provides smaller and deeper detailing with a crisp definition.

End mill bits

If you want straight cuts with spiral flutes, these are the ones for you. These bits are usually used for groove-making, pocketing, drilling and cutouts. The diameter of the bit you use will determine the type of pockets and details you get.

Ball-nose bits

These are used for bas relief carving. When these bits are used for clearing material from a wide area, small ridges are left behind in the regions where the cuts overlap, thereby creating a scalloped visual effect which might be required for some tasks. If you do not want these ridges, you can get rid of them as the step-over of the toolpath is reduced.

Fly-cutting bits

Fly-cutting bits are also known as facing or surfacing bits. The purpose of fly cutters is to make sure that the beds of CNC machines are perfectly flat. They plan the tables on the beds and can also be used for leveling the work pieces before they are machined with CNC.

Two-flute spiral bits

These are standard bits that can easily be used by amateurs. They work well with a variety of materials, including aluminum, wood, and plastics.

Some other options

If you are a pro at CNC routing, you might have to try some advanced options and work with various materials as well. These include bits designed for finer detailing, plastics, and aluminum, among other things.

How to select your CNC router bits?

It can be challenging to find the correct CNC router bit considering the various options that are available. Many factors should influence your decision. Let us shed some light on some of them.

Your project

The first thing which needs to be given utmost importance is the kind of project you have undertaken. For instance, if your work requires detailing then a V-bit might work well for you. Even in this type of bit, you will need to determine the extent of detailing you require and select the suitable included angle.

Materials

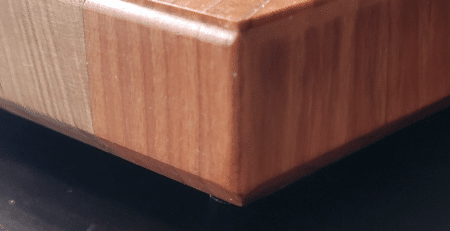

The material you are working on is another significant factor. Are you cutting softwood or hardwood? Perhaps you need to cut aluminum or fiberglass. It could also be that your project involves stainless steel or fiberglass.

If you select the wrong bit for the material, that is, something which is not compatible, it can damage your bit and even the CNC machine. Some materials that you will find easy to work with due to their versatility include 2-fluted end mill, engraving bit, and end mill and ball nose.

Manufacturers usually make bits for specific materials. For instance, plastic bits are made such that excessive melting is prevented. Similarly, hardwood bits are designed such that clean edges are provided. Aluminum bits are made such that the clear chips effectively, thereby avoiding re-welding.

Speed

You will also need to ask whether your project requires a smooth cut or a fast one. The horsepower of the spindle determines the speed and feed rate. High RPM implies that you will get a profound quality finish. At the same time, it can also cause higher friction, resulting in the wearing of the bit. Thus, you need to make sure that you read the manufacturer’s manual regarding the speed parameters of the product correctly so that you do not end up damaging it.

Higher feed rates lead to larger chips. If the chips are excessively large, there is a chance that the bit will break. However, too small chips will cause dulling of the bit. Therefore, you will need to strike the right balance, which is something that you will learn with time.

Finish

Multiple cutting edges are offered by the bits to provide you with optimal flexibility. You can opt for 2, 3, and 4-flute bits depending on your requirement. Finer quality of the cut is ensured with more flutes. However, this will make the process longer as the bit will take a longer time to cut through the material.

Final words

At the end of the day, the speed of the CNC router bit that would work for you depends on your project and requirements. For instance, if you value speed more than edge quality, single edge bits will be a better option. On the other hand, if you feel that speed can be compromised for edge quality, you will find double-edge bits to be more suitable. Spiral bits are suited when your machine has limited horsepower.

Therefore, if you want to make sure that you select the right CNC router bit, make sure that you understand the requirements of your project and the materials you will be working with.